The History of Ultrasonic Cleaners

The technology behind ultrasonic cleaners is derived from ultrasound technology, which was first discovered in a laboratory quite by accident in the 1930s. This happened when workers at the Radio Corporation of America (RCA), were using freon to cool radio components, and they noticed ultrasonic wave action surrounding a crystal operating at 300 kHz. However, they shelved the discover of ultrasonic power for years, not applying it until around 1949. Ultrasonic cleaners emerged from the lab and entered production facilities in 1952. Then, in the 1970s, people began using the technology to clean items inexpensively in the home.

Since the 1990s, the ultrasonic cleaning industry has seen many advances, as researchers have learned to clean parts using higher and higher frequencies and as they have learned to incorporate a variety of advanced cleaning actions. These include power spraying, rinsing, precision flushing and parts drying. In recent years, manufacturers have even been able to design systems that carry out these actions at such high rates of speed, that, when the ultrasonic cleaner is equipped or attached to deionized water, it produces zero residue.

Design

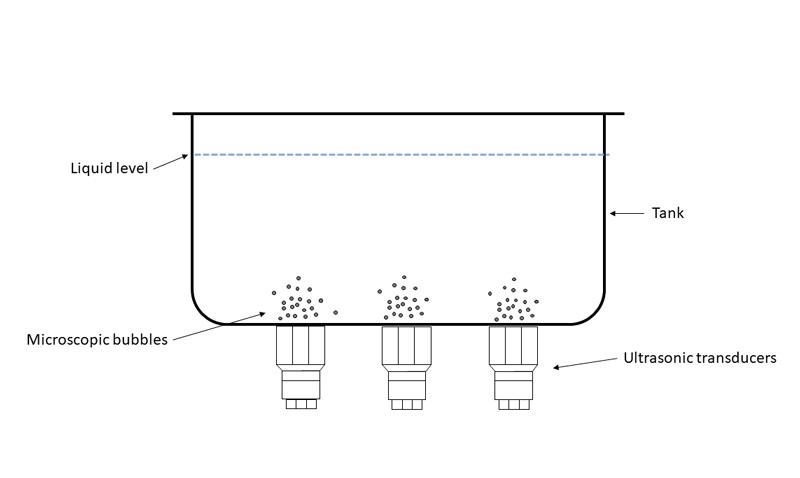

All ultrasonic cleaning equipment is at minimum equipped with an ultrasonic transducer, an ultrasonic generator, and an ultrasonic tank, also known as an immersion tank.

Transducers work by converting the energy driven by the electric current into high ultrasonic frequency mechanical vibrations. The generator provides the transducer with the electrical energy it needs to make these mechanical vibrations. Manufacturers either attach the transducer to the side of the tank or lower it directly into the tank. (The tank is where you place the parts you want to clean.) Wherever it goes, the transducer emits ultrasonic sound waves into the tank. Once inside the tank, the sound waves cause cavitation.

The tank contains an ultrasound conductive fluid; this is the cleaning solution. Typically, it based on one of three different cleaning mediums: hot water cleaning, which uses a heated water stream; aqueous cleaning, which uses a water-based ultrasonic cleaning solution; and solvent or vapor cleaning, in which the solvent is evaporated then condensed onto the surface of the parts. Once this fluid explodes into bubbles, it scrubs the parts clean. Materials to which customers commonly give an ultrasonic wash to include stainless steel, iron, aluminum, copper, brass, plastics, molded rubber, wood, and absorbent cloth.

Usually, ultrasonic cleaner parts, particularly the tank, are constructed from a material like stainless steel. This is because a stainless steel tank provides ample corrosion resistance and durability.

There are many different ways that you can customize your ultrasonic cleaning system. For example, by pairing an ultrasonic cleaner with a square wave signal, you can turn your normal ultrasonic system into a multi-frequency cleaning system with which you can work on a variety of contaminants using a diversity of vibrations and frequencies. For ease of use, you can also turn your machine into a digital ultrasonic cleaner. You can also make it mobile with the addition of casters. Finally, if your application allows it, you can choose to have your system powered by a battery instead of a transducer.

Before you begin cleaning, you must lower your parts into the cleaner tank. Once they’re in the tank, you can turn on the system. You can do this with digital ultrasonic controls or with control knobs. The ultrasonic cleaning process truly begins when cavitation occurs in the ultrasonic bath. The agitation caused by cavitation releases energy and heat so efficient that the cleaning solution cleans both the exposed and concealed surfaces of the immersed parts.

Ultrasonic cleaners are unique for one main and significant reason: They provide an unprecedented quality of cleaning. Not only do they clean every nook and cranny, but they clean them better and more efficiently than other cleaning systems.

Types

There are a wide variety of different of ultrasonic cleaners. Some of these systems are categorized by application. Examples of these include ultrasonic blind cleaners, ultrasonic jewelry cleaners, golf club cleaners, ultrasonic gun cleaners and ultrasonic degreasers.

Ultrasonic blind cleaners, as their name suggests, are designed to clean and remove contaminants like fingerprints, dirt, grease, and nicotine from blinds and shades of all kinds. Likewise, jewelry cleaners clean jewelry, golf club cleaners clean golf clubs, and ultrasonic gun cleaners clean guns. Degreasers clean the grease buildup found on automotive equipment and in parts processing. Other ultrasonic parts washers, such as industrial ultrasonic cleaners, immersible ultrasonic cleaners, and fully-automated ultrasonic cleaners, are categorized more widely.

Industrial ultrasonic cleaners work by creating high-frequency sound waves to lift debris and pollutants on the surface of the object they plan to clean. In addition to employing an ultrasound wave, to clean dirt from the industrial parts, the device also makes use of a customized solution and a robust electric heater that warms it. Immersible ultrasonic cleaners offer many advantages including high flexibility and ease of operation, installation, and endurance.

Fully-automated ultrasonic cleaners improve upon conventional models of ultrasonic cleaning equipment because they increase pre-assembly cleaning quality and cut solvent use by ninety percent. These improvements are the result of harnessing heat pump thermal transfer techniques which serve to minimize solvent evaporation that occurs overnight. Combined with diagnostic process control, full-automated ultrasonic cleaners offer a dedicated computerized work transporter that facilitates, establishes and maintains optimal performance levels.

Advantages of Ultrasonic Cleaning Equipment

Ultrasonic cleaners deliver a superior level of clean that no conventional parts cleaning system can provide. This, however, is not their only advantage. They are also environmentally friendly, cost effective, time efficient, versatile, gentle, energy efficient, reliable and able to clean the smallest parts.

1. Environmental Friendliness: Ultrasonic cleaning offers reduced biodegradable waste, emissions, and a safer working environment.

2. Cost Effectiveness: Since ultrasonic cleaning utilizes soap-based solutions in combination with sonic energy, it has minimal operating costs. The cost per operation can vary a little, depending on the type of cleansing agent used and the parts being cleaned. However, it is marginal in comparison to other options.

3. Time Efficiency: The time required to clean metal parts using ultrasonic cleaning is relatively short, so you’ll see great savings on your energy bill.

4. Versatility: Using ultrasonic industrial parts cleaners, you can clean up almost every variety of pollutants and particulates. Oil, grease, metal chips, cutting fluids, dirt, dust, sand, metal melts, paint, shavings, carbon, sulfur, oxides, and many other elements are in the list of contaminants that these intelligent devices can eradicate.

5. Gentleness: To clean parts and remove debris, ultrasonic cleaners do not rely on abrasion, scrubbing, spraying, vacuuming or the like. Instead, they offer a much gentler solution. Ultrasonic is so gentle that you can even use it to clean the delicate microchips of phones and laptops.

6. Energy Efficiency: In comparison with traditional industrial parts washers, ultrasonic cleaners consumer much less power. While other washing machines have scores of motors to perform different actions, ultrasonic washing machines have just one motor to carry out different exercises. Furthermore, the cleaner motor is usually designed to work efficiently without consuming too much electricity.

7. Reliability: Ultrasonic technology centers on effective and reliable parts washing. There is no moving or rotatory part in this application. To put it simply, ultrasonic cleaning devices do not work on a rotating mechanism. For that reason, ultrasonic washers keep working reliably and constantly.

8. Small Parts Cleaning: When you are working with ultrasonic cleaners, there is no need to worry about small machine parts. This cleaning system offers an ease in washing small parts that are typically tough to wash with conventional systems. In addition to this factor, you can perform cleaning even within open and deep sections of machine parts. Ultrasonic cleaning machines prove very effective for parts with passageways, small openings, cracks, and holes.

Accessories

Ultrasonic washers do not require many accessories, as their work is pretty straightforward. However, there are some available to you, should they suit your application. Examples of these include extra sinks, casters for mobility, hinged and/or insulated lids and containment baskets.

Installation

There are a number of different places you can set up your ultrasonic cleaner. For example, you can have it mounted on a table or in a frame, assembled next to walls that are installed with transducers or placed as a self-contained unit.

No matter where you put it, make sure that it is close to a standard grounded electrical outlet. Before you plug it in, make sure that your system’s power requirements match that of the outlet.

Proper Care for Ultrasonic Cleaners

If you run your cleaner safely and normally, it will rarely require maintenance. So, the key is to follow best practices and keep an out for defects.

For example, a bad practice among operators is to put parts directly at the bottom of equipment's tank, which damages the transducers. The best practice is to use a basket instead. Meanwhile, the most common defect with used ultrasonic parts cleaners is heat damage. Ultrasonic transducers release quite a bit of heat, which is dispersed in the liquid or solution in the tank, and running a unit with a low-level of solvent can effectively damage the bonding between the transducers and the tank, preventing cavitation. To check for heat damage, see there is any discoloration on the housing.

In addition, to make your ultrasonic cleaning equipment work even better and last even longer, you need to keep it at the right temperature (typically between 135? and 150?), make sure you have the right watt density and right output frequency (standard ultrasonic washers work at 40 kHz, or 40,000 cycles per second; the 40-kHz rate maximizes equipment life expectancy) and select the right cleaning solution.

Standards

The standards to which you adhere depend partly on your application and partly on government/industry standards. For example, if you plan to clean parts for medical purposes, your cleaner must be up to FDA standards. If you plan to clean military equipment, your part washer will likely need to meet Mil-Specs. In addition, for the best results, make sure your system and your practices are up to the code of standards organizations like ISO, ASTM, and NIST.

Things to Consider

The first thing to think about is what you plan to clean. Specifically, think about the shape, size, and quantity of parts you want to clean. This will help you pick the tub size of your ultrasonic cleaning equipment. You can purchase an ultrasonic cleaning tank with just about any capacity.

When picking out your ultrasonic part cleaner, you also need to consider the nature of your application. For the heaviest duty cleaning jobs, consider high-capacity ultrasonic cleaners, which are significantly sturdier than their standard counterparts.

Also carefully consider your cleaning solution. Cleansing agent types can be alkaline, acidic or neutral. The choice of which depends on the parts you’re washing. For example, while alkaline solutions work very well on hard metal parts like stainless steel, they can damage some non-ferrous metals and softer metals like aluminum. Likewise, don’t clean stain prone steel and other ferrous metals with water-based solution; they need a built-in rust inhibitor and rinsed in a rust inhibitor to be washed effectively, without any harm to the metal. Neutral pH cleaners are needed to clean delicate parts like copper filaments or thin layers of metal. Mostly, they’re used with ultrasonic jewelry cleaner solutions.

To help you reach the right conclusion and build you the best cleaning system, you need the right manufacturer. This manufacturer will go the extra mile and treat you like you’re their only customer. They’ll make sure that you get a solution that works within your specifications, requirements, budgets, and timeframe. To find the right manufacturer for you, check out the companies listed above.